Solutions

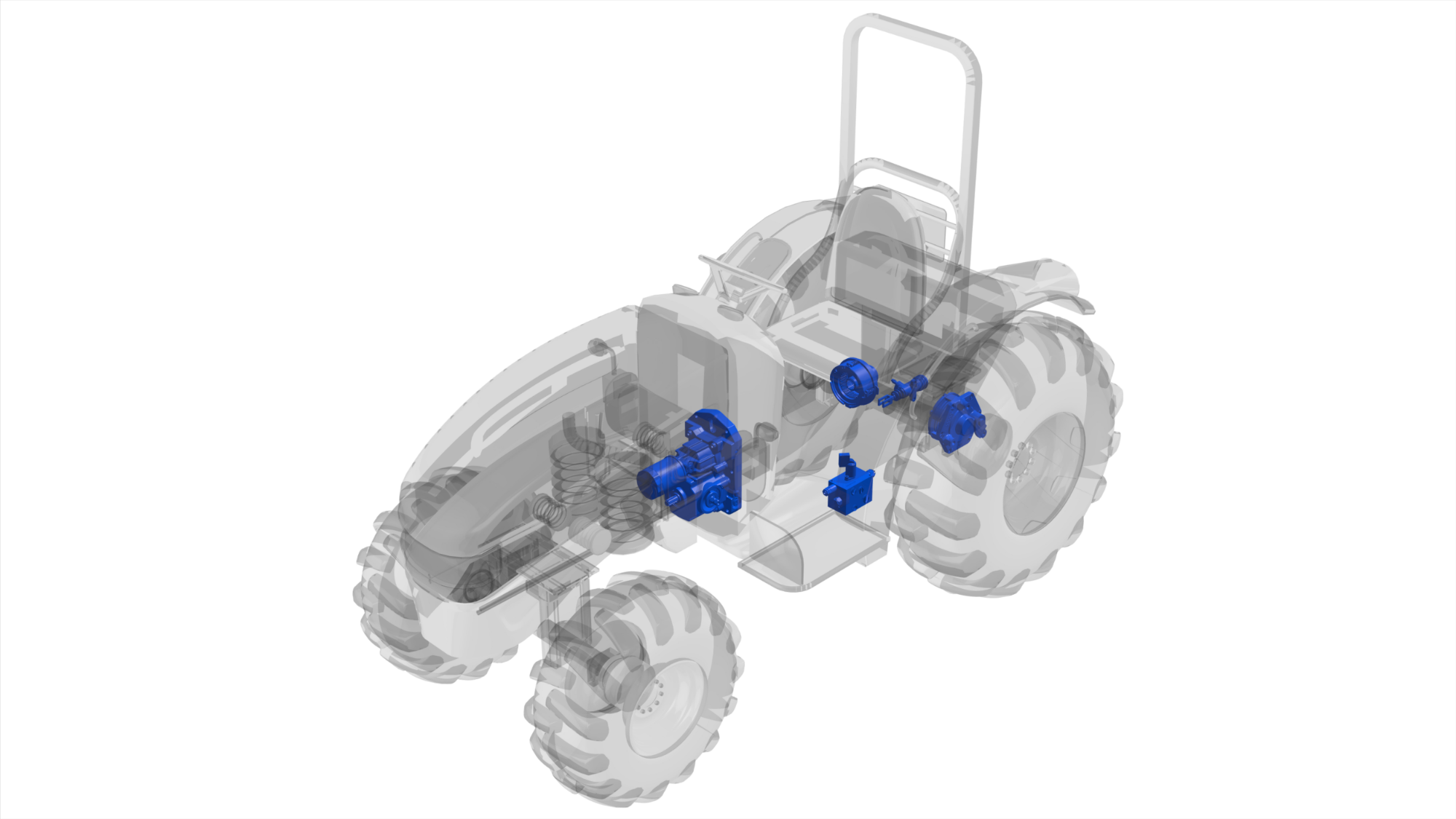

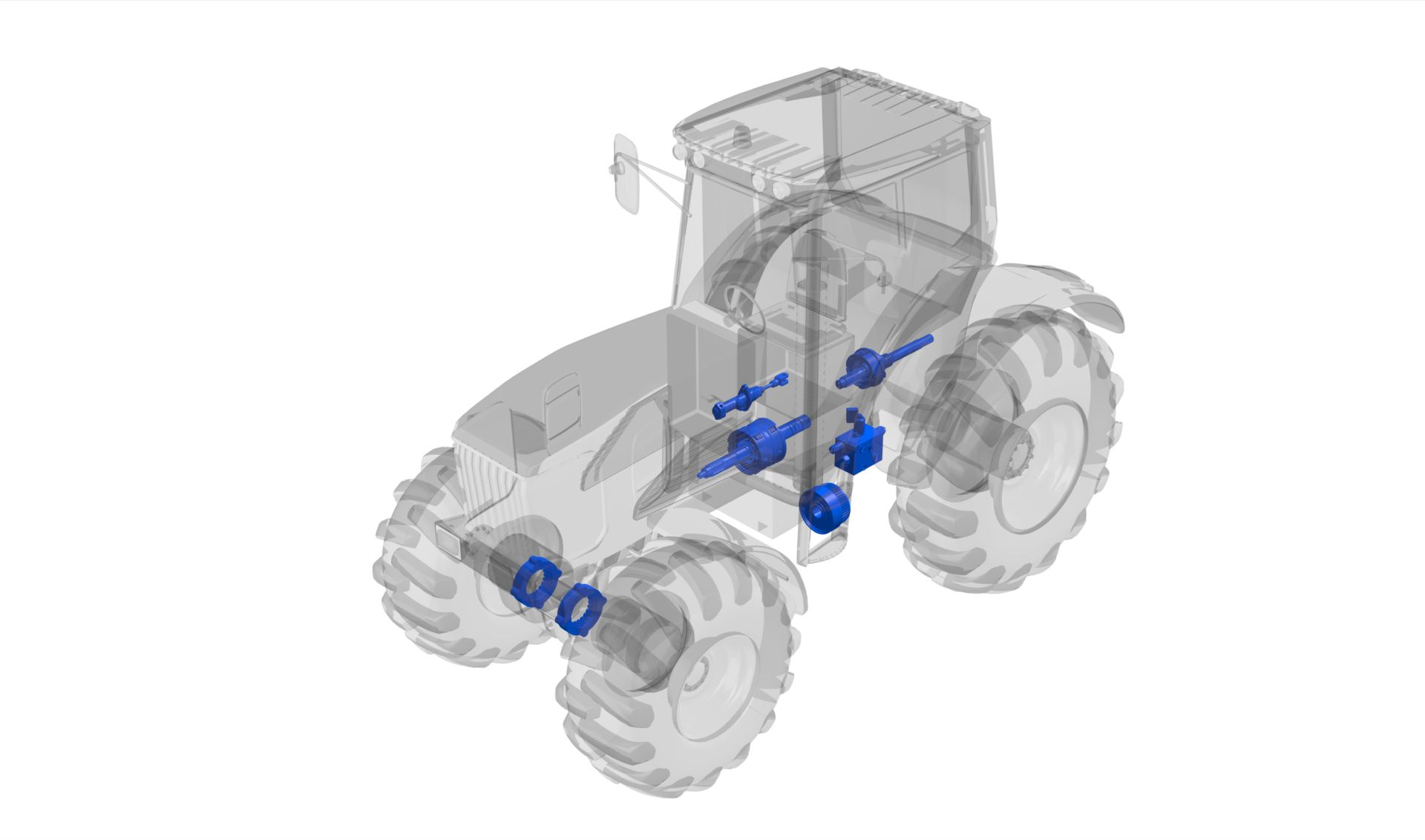

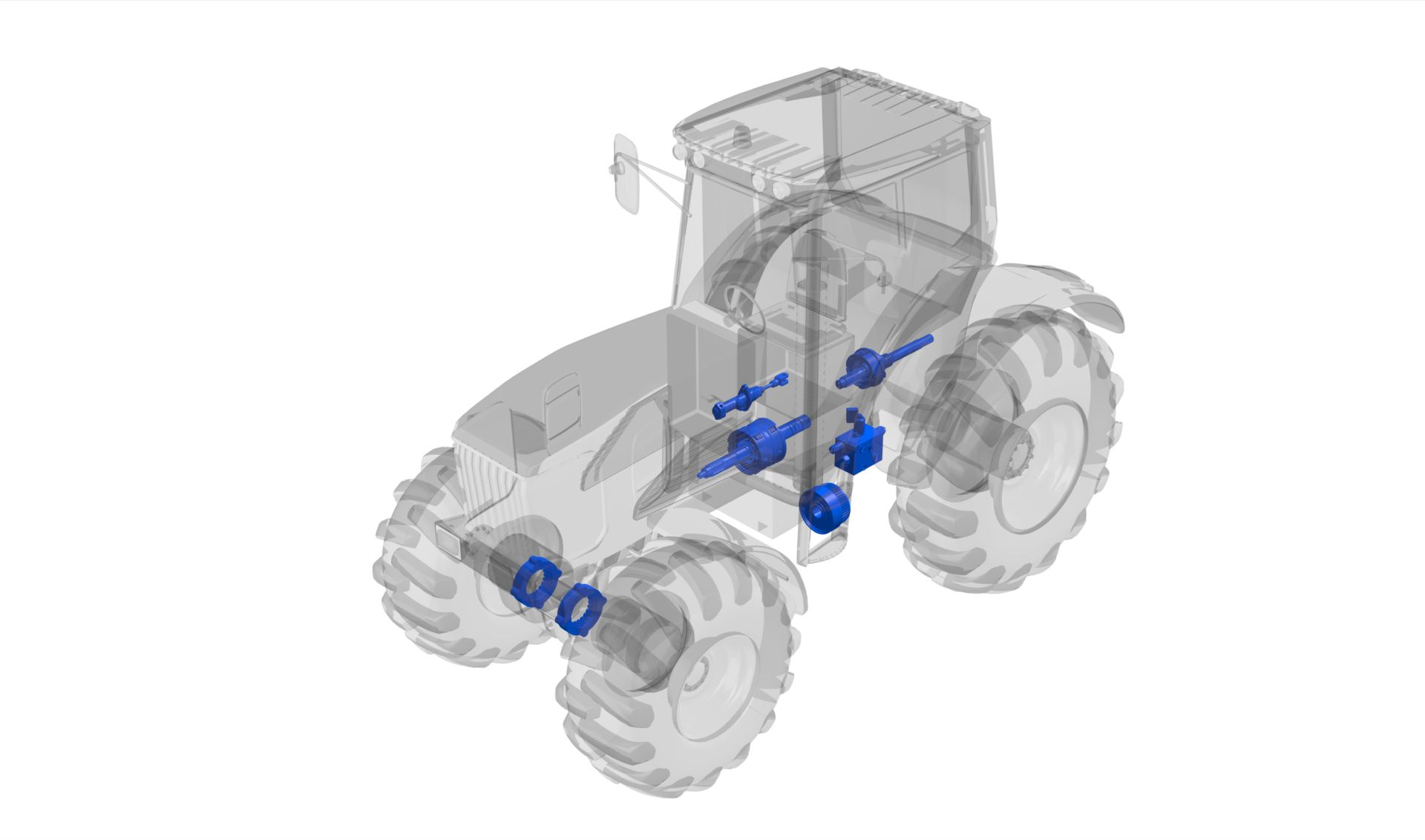

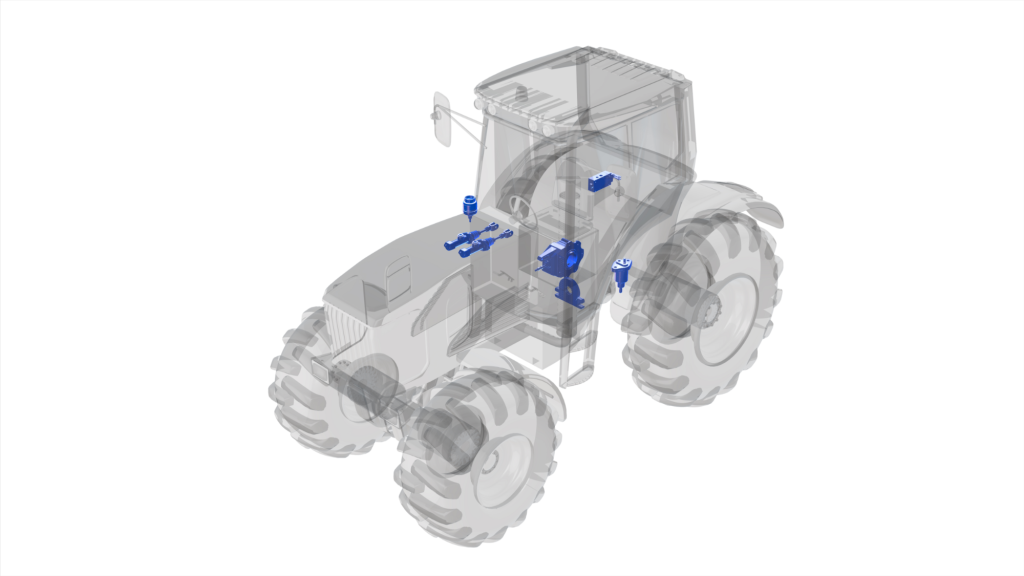

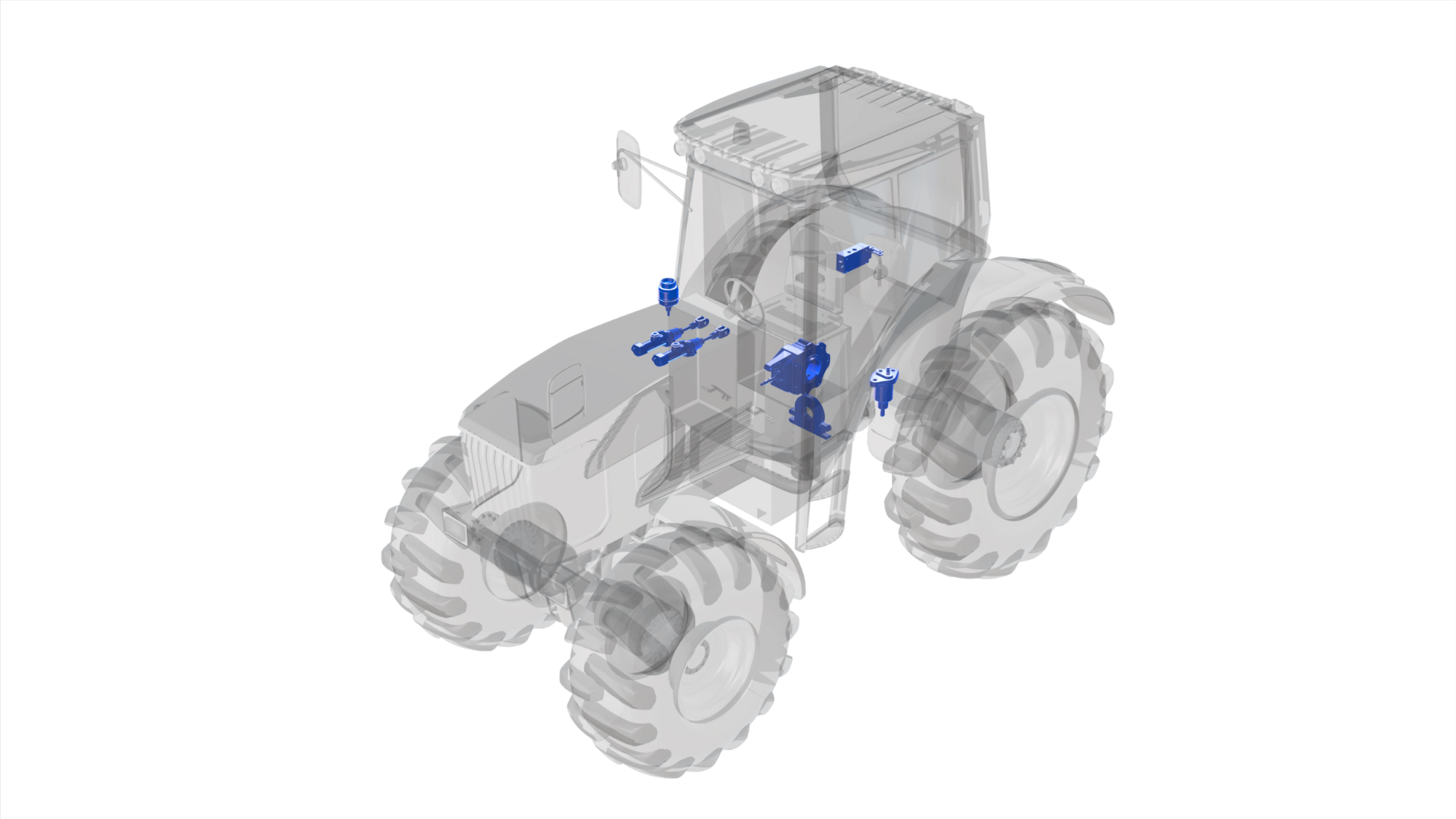

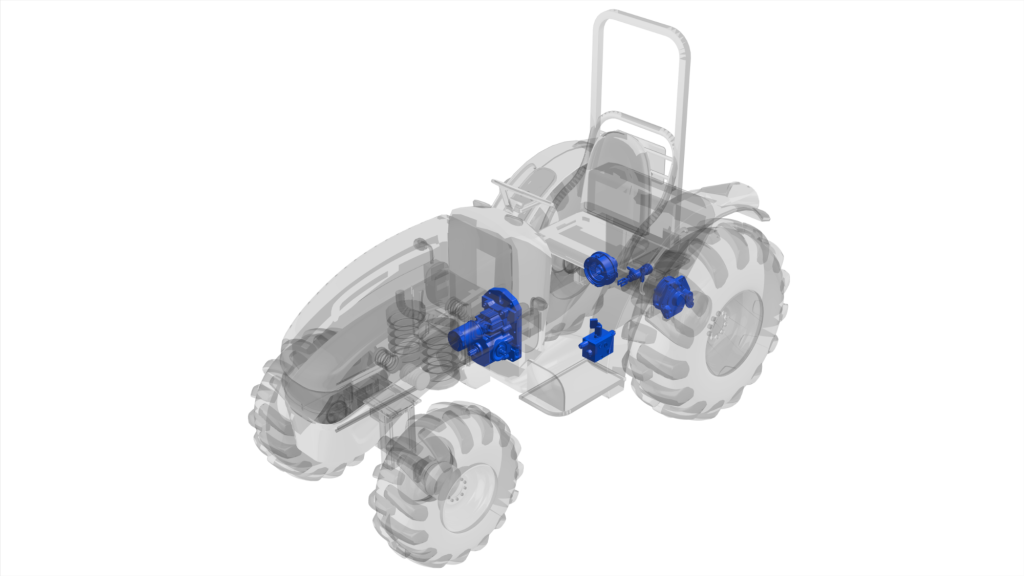

Agriculture

- Clutch

- Brake

- Compact

Master Cylinder

JMI’s Master Cylinder is a crucial component in Brake and Clutch systems, converting brake pedal force into hydraulic pressure, and can be customized for optimal performance.

Power Shuttle Clutch

JMI’s Master Cylinder is a crucial component in Brake and Clutch systems, converting brake pedal force into hydraulic pressure, and can be customized for optimal performance.

Many Fold Valve Assy

JMI’s Master Cylinder is a crucial component in Brake and Clutch systems, converting brake pedal force into hydraulic pressure, and can be customized for optimal performance.

4WD Clutch

JMI’s Master Cylinder is a crucial component in Brake and Clutch systems, converting brake pedal force into hydraulic pressure, and can be customized for optimal performance.

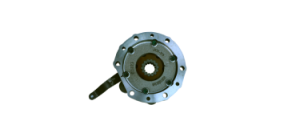

IPTO Clutch Assy

JMI manufactures high-quality IPTO clutches, ensuring efficient power transfer from engines to auxiliary systems.

LSD Clutch Pack

Designed for high-performance and off-road applications, JMI’s wet clutch limited slip differential (LSD) enhances traction and stability by engaging friction discs in oil, ensuring smooth operation and preventing excessive wheel spin.

Parking Brake

JMI’s parking brake with ball ramp actuation provides a reliable power transfer solution, ideal for long-term use in hallenging, muddy environments.

Pantograph Brake

Customized wet brake is designed in 3 to 9.25 inches, featuring an oil-immersed assembly to prevent foreign particles and maintain transmission oil for cooler operation.

Slave Cylinder

JMI’s Slave Cylinders are compatible with DOT3, DOT4, and Mineral oil, converting hydraulic pressure to mechanical force for brakes and clutches, with customization options including Normal, Self-Adjusting, and Integrated Concentric.

Trailer Brake Valve

JMI’s Trailer Brake Valve is known for its unwavering dedication to safety, providing precise control over braking force to ensure synchronized and effective trailer braking.

Reservoir

The reservoir is designed to store brake system oil and supply it to the brake system when the brakes are applied. It features a built-in brake oil level indicator sensor to alert the driver of the oil level.

Mass Cylinder

JMI’s Master Cylinder is a crucial component in Brake and Clutch systems, converting brake pedal force into hydraulic pressure, and can be customized for optimal performance.

IPTO Clutch Assy

JMI manufactures high-quality IPTO clutches, ensuring efficient power transfer from engines to auxiliary systems.

Auto Brake Cylinder

The Auto Brake Cylinder integrates with a solenoid valve and ECV control arrangement, automatically applying brakes based on steering angle for enhanced safety and control in infield applications. This innovative system eliminates the need for manual brake pedal force, making infield operations more efficient and user-friendly.

Cam Break

Custom cam-operated wet brake includes actuator plates, retaining springs, cam, and lever. They supply complete assemblies or offer flexible options based on customer requirements.

Manifold Valve

The Manifold Valve provides precise flow, pressure, and modulation control for various clutch applications, ensuring optimal performance and efficiency.

HST

JMI’s HST (Hydrostatic Transmission) has efficient power transmission for agricultural machinery like E-Tractors, Combine Harvesters, Rice Trans planters, and Sprayers, eliminating gear shifts.